People in the cable industry all know that the messenger wire provides support and strength for cables, and the durability of the messenger is vital as well. However, few people know what factors can enhance the durability,

the reasons behind the existence of messengers with Phosphatized and Galvanized steel wire, and the real differences between them. FOTUX, a company with 25 years of experience in cable manufacturing, will provide you with the answers on this page.

Contrasting Processes: Galvanized vs. Phosphatized Steel Wires

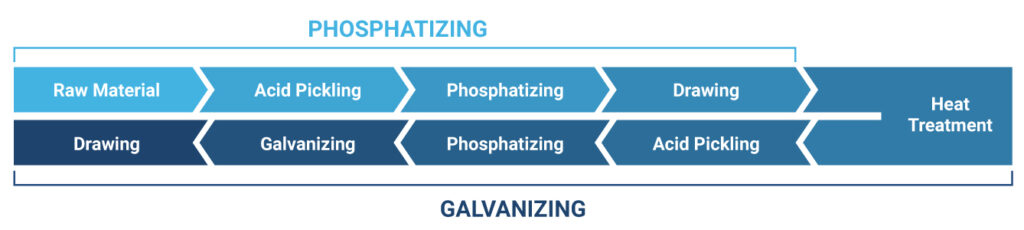

Both of Phosphatizing and Galvanizing processes aim to establish an anticorrosion layer on the surface of the steel wire, which is a pivotal factor in determining its durability. Let’s take a closer look at the treatment processes of messenger wire with 1mm diameter as a first step towards understanding the distinctions.

The graphic above is obvious to tell you that the Phosphatizing is just the preliminary process of Galvanizing. You must have the answer that this also means the different performance of anticorrosion.

Outstanding Performance of Galvanized Steel Wire

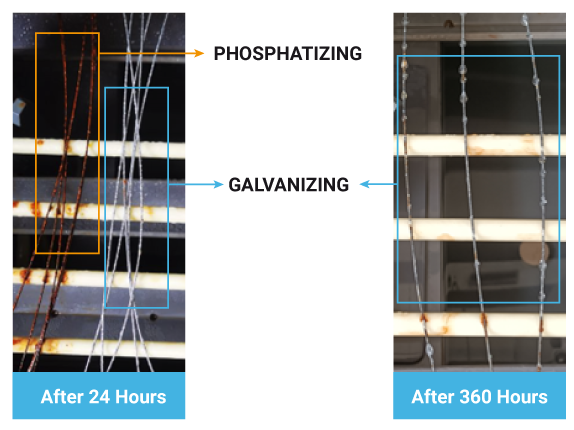

In order to show you the most noticeable performance difference, the salt spray test was conducted according to ASTM B117 in FOTUX Lab.

| Item | Breaking Load Before Test (N) | Duration of Corrosion | Breaking Load After Corrosion (N) |

| Galvanized | 1668 | 360 hours Max. | 1583 |

| Phosphatized | 1614 | 24 hours Max. | 1583 |

The data and images above verify that there is a huge gap of the anticorrosion performance. FOTUX adheres to a responsible attitude towards product quality, and galvanized wire is the only choice we offer to our valuable customers.