FOTUX’s meticulous attention to design, material choice, and production precision, all ensures that our connectors meet the rigorous demands of high-performance fiber connections…

Unraveling the Ferrule of Fiber Fast Connectors

Producing high-quality fiber fast connectors requires more efforts and attention compared to other connectors. For instance, selecting high-quality ceramic head ensures precise alignment of the fibers, while using high-performance matching gel effectively fills the tiny gaps between the fibers. Additionally, the critical step of end-face cleaning during assembly helps eliminate small contaminants, reducing the risk of product failure. However, simply considering these aspects is not enough. A finely designed ferrule system plays a more crucial role in the reliability of the fiber connectors.

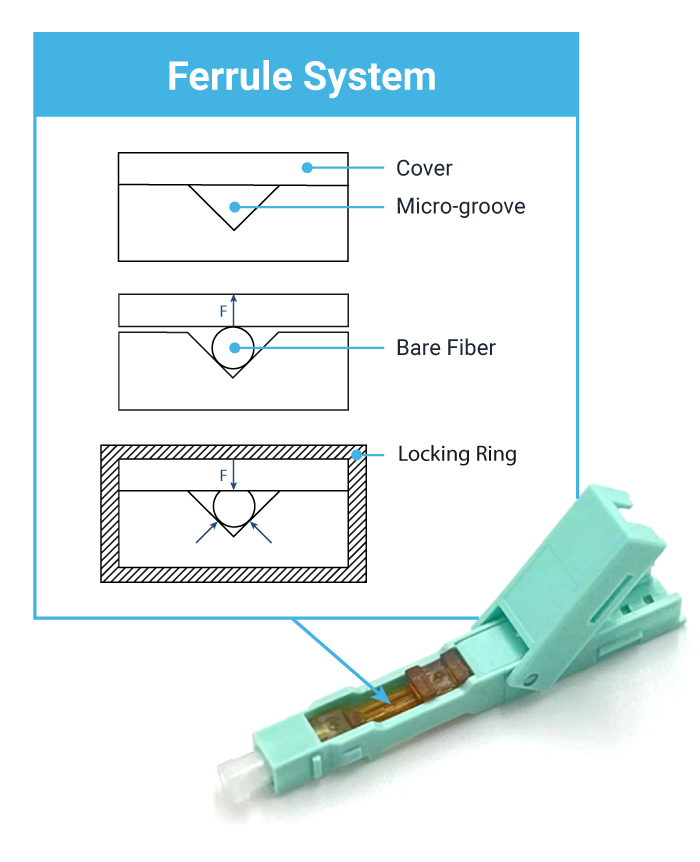

Mechanical Principles of the Ferrule System

When installing the connector on-site, the bare fiber is guided into the ferrule along the Micro-groove. As the fiber fills the Micro-groove, it lifts the upper Cover slightly. By toggling the Locking Ring, downward pressure is applied to the Cover, securing the bare fiber firmly in place and achieving a stable connection with the embedded fiber within the ferrule.

In practical application, the retention force of the ferrule system on the bare fiber should be ideally controlled between in narrow range of 2 to 3N. It can lead to poor fiber contact which cause increasing of the connector’s attenuation and signal interruption if the force is too low. This issue is particularly problematic under vibration. On the other hand, excessive pressure can cause fiber glass deformation, increasing signal attenuation. In the worst scenario, it may damage the fiber, leading to transmission disaster failure.

What Has FOTUX Been Doing for A Reliable & Durable Ferrule System?

Controlling the retention force of the bare fiber within an optimal range significantly depends on a reliable ferrule system, for FOTUX fast connectors, every detail is precisely tailored and engineered. This includes the depth of the Micro-groove, the thickness of the cover plate, and the width of the Locking Ring, etc. Each component is crafted using high-precision molds to maintain consistency between the design and the real-time product, high-quality virgin PEI as the material for ferrule is selected to ensure sufficient hardness and strength across a wide temperature high and low cycling.

FOTUX’s meticulous attention to design, material choice, and production precision, all ensures that our connectors meet the rigorous demands of high-performance fiber connections even under the harsh application environment, offering users a dependable and efficient installation experience.